One thing that we have covered a lot in Smart Data Collective is how artificial intelligence helps businesses protect and improve supply chains. You can see clear changes across industries as companies turn to AI to reduce disruptions, increase reliability, and prepare for demand swings.

Businesses around the world are expected to pay $244.22 billion on AI for various reasons this year. You may notice that many of those investments are focused on logistics, inventory management, and predictive forecasting. Keep reading to learn more.

AI Is Becoming the Norm for Supply Chain Resilience

There are 333.34 million companies using AI, according to Anthony Cardillo of Exploding Topics. That accounts for nearly 90% of all businesses globally, showing how common this shift has become. It is clear that AI is no longer an experiment—it is a standard part of how supply chains are protected from risks.

Precedence Research reports that global businesses spent $7.15 billion on AI technology to improve supply chains last year. You might be surprised by how quickly that figure has grown, especially since many companies are still recovering from pandemic-era supply shocks. There are several types of tools being purchased, from AI-based demand forecasting to automated warehouse systems.

You see fewer delays and stockouts when AI models predict shipping issues early. There are also fewer cases of oversupply, thanks to more accurate tracking of demand patterns. You can reduce waste by adjusting inventory in real time based on regional sales. It is not just big companies doing this—many smaller businesses are following the same trend.

It is getting harder for any company to compete without some form of AI support in their supply chain. You should expect even higher spending next year as more firms find ways to cut risks and stay ahead. There are strong signs that the global supply chain will look very different just a few years from now.

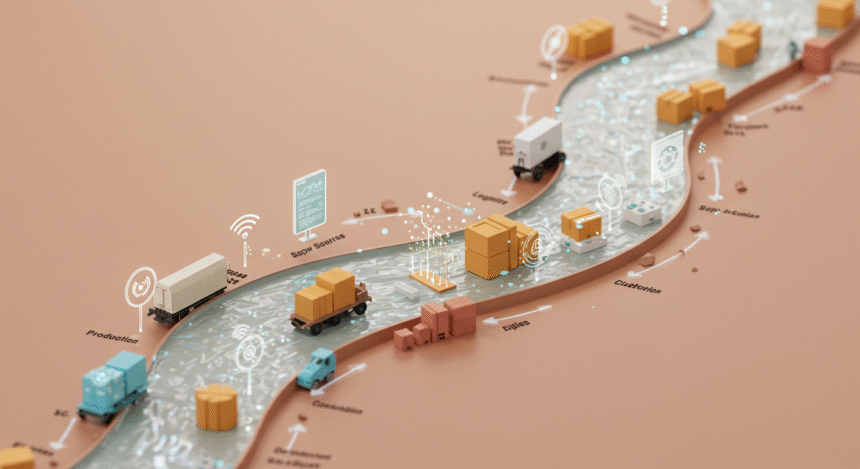

In today’s competitive and fast-moving market, companies can no longer afford to work in silos. Every product that reaches a customer is the result of countless processes, materials, and relationships stretching across the globe. The strength of these interconnected parts lies not only in their individual functions but in how well they communicate and collaborate. That’s where supply chain collaboration becomes essential, not just as a strategy, but as a necessity.

Why Collaboration Matters More Than Ever

Businesses once focused heavily on optimizing their own internal operations. But over time, it became clear that efficiency at a single point in the chain isn’t enough. If a supplier experiences delays or a distributor misjudges demand, the entire system feels the strain. That’s why communication, visibility, and trust among all players, from suppliers to manufacturers to logistics partners, are critical. Shared goals, real-time data exchange, and aligned priorities can prevent bottlenecks and enable faster, smarter decisions.

Challenges That Push Companies Toward Closer Cooperation

Several external pressures are driving organizations to rethink how they interact with partners:

- Global Disruptions: Events like pandemics, political instability, or natural disasters can instantly throw global supply lines into chaos. When businesses work closely with suppliers, they can adjust quickly to changing conditions.

- Rising Customer Expectations: Today’s consumers expect fast delivery, custom options, and full transparency. To meet these expectations, companies must work hand-in-hand with suppliers and logistics firms.

- Sustainability Goals: Environmental concerns require businesses to look at the bigger picture. Working together allows companies to streamline processes, reduce waste, and minimize carbon footprints.

These pressures are not going away. In fact, they’re becoming more complex. That’s why building strong relationships along the chain is no longer optional; it’s essential for survival and growth.

Benefits of an Integrated Approach

When partners across a supply network begin to operate as a unified team, the advantages go beyond just avoiding delays. Collaboration unlocks innovation. For example, a supplier might suggest a material that reduces costs and increases durability, but without an open channel of communication, that idea might never be shared.

Better forecasting is another key benefit. By sharing sales data and market insights, retailers and manufacturers can avoid overproduction or stockouts. This not only reduces waste but also improves customer satisfaction.

Furthermore, collaborative planning leads to better risk management. If all parties are aware of potential issues ahead of time, whether it’s a shortage of raw materials or a shipping delay, they can act together to find a solution. This proactive mindset is only possible when businesses are aligned and transparent.

Technology as a Collaboration Enabler

Technology plays a vital role in bringing these partnerships to life. Cloud platforms, digital dashboards, and real-time analytics are breaking down the walls between companies. They allow for instant updates, shared visibility, and collaborative decision-making, even across continents.

A prime example of this is how companies are adopting product lifecycle management systems. These tools allow every stakeholder to work from the same data set, ensuring that changes in design or production are immediately visible to everyone. In one instance, a company seeking stronger product traceability adopted a digital platform to improve engineering oversight, which naturally led them to improve supply chain collaboration as well.

By embracing modern tools, businesses can make their networks smarter, more agile, and more resilient.

Building a Culture of Trust and Transparency

Of course, tools alone aren’t enough. True collaboration requires a cultural shift. Companies must be willing to share data, open their books (to a degree), and work toward mutual success rather than individual gain. It’s about moving from transactional relationships to long-term partnerships based on trust.

Regular meetings, shared performance metrics, and joint planning sessions can all help foster this mindset. When everyone knows that their success is tied to the success of their partners, collaboration becomes second nature.

Final Thoughts

In a world where supply chains are becoming more complex and volatile, collaboration is the key to resilience. Businesses that embrace openness, integrate new technologies, and build genuine partnerships will be far better equipped to thrive. As industries evolve, it won’t be the fastest or the biggest companies that win, but those that work best together.