In December, we published an article talking about how more companies are using AI technology to solve a number of challenges they face. The manufacturing sector is no exception.

Markets and Markets estimates that global manufacturers spent over $3.2 billion on AI last year. That figure is likely going to increase even further in the years to come.

One of the many ways that AI is changing manufacturing is with the inception of smart factories. John Edwards, a Technology Journalist & Author for InformationWeek, reports that smart factories are revolutionizing manufacturing.

“Businesses in these industries often have complex manufacturing processes with many moving parts, which makes them excellent candidates for a smart factory,” Johnson explains. “Additionally, businesses that wish to reduce costs, improve efficiency, have a high focus on quality control, and want to to be very agile and responsive to change, will likely benefit from a smart factory deployment.”

Smart factories powered by Artificial Intelligence are transforming how we approach production in our modern era. This automation and data processing symphony promises incredible efficiency and productivity gains across the entire sector. This is just one of the many ways machine learning is driving major changes in the manufacturing sector.

This industrial evolution hinges, however, on a critical partnership between Operational Technology (OT) and Information Technology (IT), working seamlessly together. The increased connectivity within smart factories also significantly increases the attack surface for cyber threats. Manufacturers who wish to protect their assets and staff should consider seeking the assistance of industry specialists for an OT security solution.

Smart Factories

AI is changing the manufacturing sector by leaps and bounds, introducing intelligent automation and communication into processes. This, in turn, has significantly improved manufacturing efficiency.

This is especially true in the following three key areas:

Predictive Equipment Maintenance

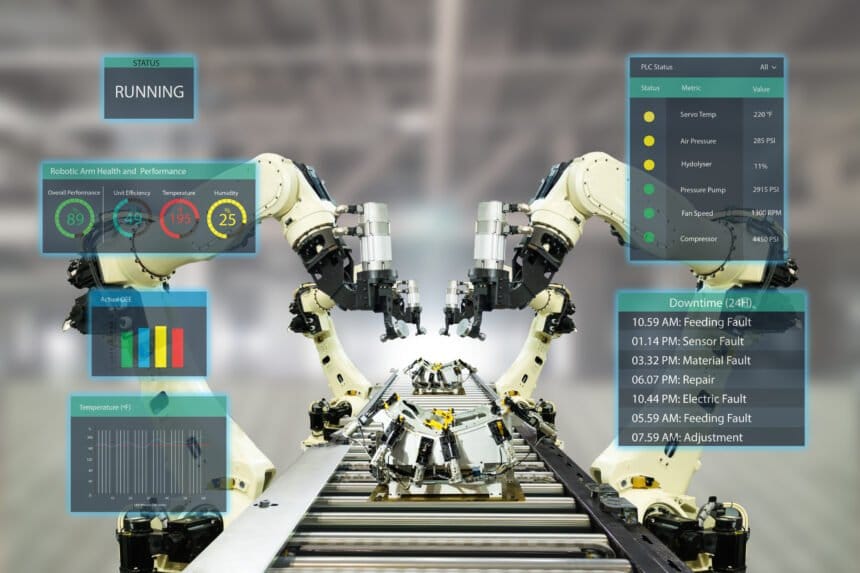

All manufacturing plants must keep their equipment running smoothly and within the defined parameters. AI can provide the up-to-date information necessary for maintaining manufacturing equipment.

Factory maintenance schedules can be created using networked sensors combined with AI. Avoiding possible manufacturing defects, by preempting machine failure. Even the slightest possible indicators, such as minute temperature variances, can prove indispensable.

Imagine a world where factory machines initiate maintenance and order the parts they need ahead of time. With AI integrated into manufacturing, this can become a reality.

Production Quality Control

AI brings advantages to manufacturing hubs regarding quality control of products being turned out. This ranges from sensors that can test products while they are assembled to quality verification of batches of products after final assembly.

Modern AI is flexible and can adapt to changing manufacturing parameters and environmental conditions. It controls the plant using real-time data collection from a myriad of interconnected sensors, such as heat and air pressure. Consistently improving its model over time. This benefits both the manufacturing process and leads to consistent overall product quality.

Quality products directly translate to returns on investment and an improvement in the manufacturer’s overall reputation in the industry and to customers.

Robotics Aided Manufacturing

Due to the vast improvements in industrialization, using robots in manufacturing is nothing new. Introducing AI into how these robots function makes them more than just machines but powerful, adaptable tools. Tools that can be learned alongside humans improve assembly line effectiveness and safety.

Role OT/IT Convergence Plays in Smart Factories

Convergence between OT and IT is central to the success of Smart Factories.

While OT is concerned with collecting information from sensors and driving production, IT is concerned with managing communication and securing the organization’s attack surface. With OT being more exposed to cyber threats, the convergence between these technologies enables manufacturers to protect their mission-critical equipment from cyber threats while enjoying the benefit of interconnectivity and AI.

This allows the production of high-quality products by tapping into real-time data, which improves decision-making, planning, and accurate forecasting. By implementing an OT security solution, manufacturers can ensure that cybersecurity measures are attended to, defending critical data and infrastructure.

As we develop, manufacturing will only become increasingly connected with AI. This AI revolution needs the critical convergence of OT and IT to safeguard against malicious threat actors. Smart Factories and specialized OT security solutions will become a common sight, and rightly so. The benefits of this convergence are evident.

Conclusion

Let’s face it: AI is part of our lives now and will only become more versatile. It is no different in the manufacturing industry. AI can effectively predict machine failures and accurately detect defective products through the powerful convergence of OT and IT.

This pseudo, albeit evolving, intelligence can fast-track manufacturing processes and improve occupational safety on the production floor. Furthermore, AI can improve the efficiency of real-time processes.

Isolated by its nature, OT has customarily been more secure, without any need for cyber defense. However, keeping threat actors at bay should also be a top priority for manufacturers. Accidents due to malicious tampering via IOT connectivity should be guarded against at all costs. Plant disasters do not endanger only employees but could have a metropolitan-scale ripple effect, taking lives and impacting the environment.

The gap between OT and cyber security can be successfully breached by converging these technologies. Paving the way for securer industries.