When you buy a new piece of furniture, the typical expectation is that delivery will happen in a timely fashion. It’s understood that custom-ordered furniture might take more time to arrive, but a standard piece picked out in the store? That shouldn’t be a hassle.

When you buy a new piece of furniture, the typical expectation is that delivery will happen in a timely fashion. It’s understood that custom-ordered furniture might take more time to arrive, but a standard piece picked out in the store? That shouldn’t be a hassle.

What if you picked out a piece of furniture in the store or on a website and were told that delivery wouldn’t take place for six or even eight months? That’s precisely what happened to some Restoration Hardware customers recently, and the issue boiled down to poor supply chain planning.

Restoration Hardware’s Supply Chain Planning Disconnect

According to a recent article, customers who ordered a desk through Restoration Hardware’s new RH Modern line this past spring faced repeated delays. The company admits that they gave suppliers deadlines that were too short.

A product launched with poor supply chain planning can put a company at risk. Though not the only factor, supply chain woes cratered Restoration Hardware’s stock. The stock price went from trading at over $100 last November to around $30 today. Supply chain planning matters a great deal, and many companies are now leveraging big data to avoid such catastrophes.

The Growing Awareness of the Power of Big Data

Tech.Co recently reported that the amount of business data collected is growing at a rate of approximately 59 percent annually. While first used mainly for sales and marketing, big data analytics are increasingly used to address various supply chain challenges. A growing number of manufacturers recognize Big Data’s ability to improve their response to volatile demand and to reduce supply chain risk.

How Big Data is Addressing Modern-Day Supply Chain Challenges

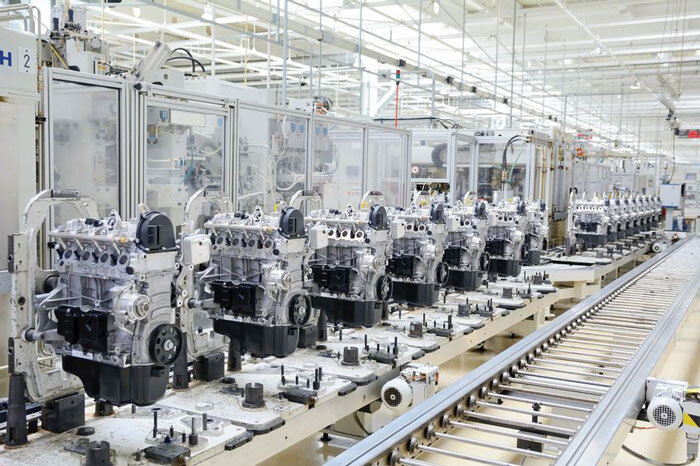

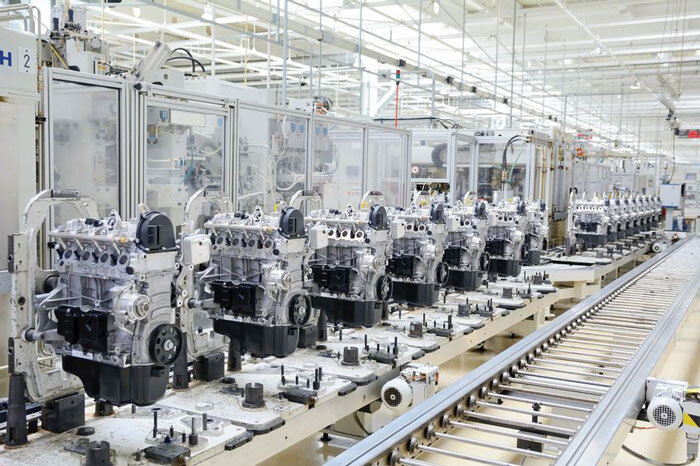

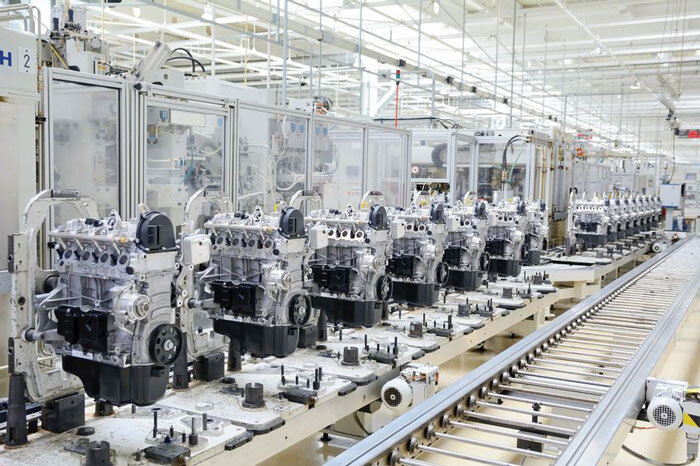

Most legacy Enterprise Resource Planning (ERP) and Supply Chain Management (SCM) systems are struggling to adapt to modern-day businesses that require shorter product lifecycles and rapid scaling. Here are just five ways that Big Data analytics are helping companies to overcome some of their biggest supply chain challenges.

- Improved Supply Chain Efficiency. Better efficiency equates to lower costs and higher profits. According to an Accenture Study, the use of big data analytics could increase supply chain efficiency by 10 percent or more.

- Enhanced Supply Chain Traceability. Big Data reduces issues with product traceability in a supply chain and reduces the cost involved should a product recall ever occur.

- Better Assessment of Supply Chain Risk. Supply chain risk management has much to do with the predictability in the supply chain. Through the use of modeling using historical data and scenario mapping, this risk can be minimized.

- More Accurate Anticipation of Customer Needs. As demonstrated at the beginning of the article, the failure to meet customer expectations can be disastrous. Big Datacan help companies predict demand levels and line up their supply chain resources accordingly.

- Improved Reaction Time in Volatile Markets. Big Data analytics can help companies compete in short product life cycles and trend markets where getting a product produced quickly is critical.

Big Data analytics is revolutionizing today’s supply chain management. In addition to the challenges just mentioned, these solutions are allowing companies to forge closer relationships with suppliers, discover new markets for products, and tighten up lead times through the use of predictive lead time technology. All of these solutions are placing products into the hands of customers more quickly and efficiently, enhancing the bottom line of manufacturers.